-

Recent Posts

Recent Comments

Archives

Categories

Meta

PrepAdd™

PrepAdd website

A better tasting colonoscopy prep

Dear Website Reader,

We’re all friends here. One day you will need to get a colonoscopy. Everything that you have heard about the prep tasting awful, is true. At some point in-between drinking the first 1/2 gallon of prep and running to the toilet, you’ll say to yourself, “why can’t they make this stuff taste better”. Then, realizing you still have another 1/2 gallon to go, you’ll swear to any higher power that “you’ll pay anything to make the stuff taste better”.

Well, we have figured out how to make the stuff taste better. It’s all about increasing the user experience, one rectum at a time.

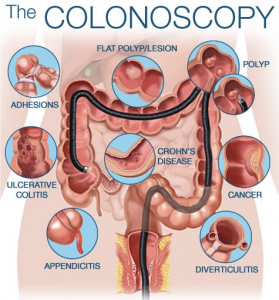

Background: Colon cancer is bad. It is the third most commonly diagnosed cancer and the second leading cause of cancer deaths in men and women combined in the US. The American Cancer Society estimates 150,000+ people were diagnosed last year and 50,000+ will die from colon cancer. The test to screen is a colonoscopy, which is an endoscopic examination and requires the bowels to be completely cleansed prior to the procedure. A colonoscopy prep is a prescribed oral solution that is an osmotic laxative indicated for cleansing the colon for preparation prior to a colonoscopy procedure. According to a 2015 consensus document for adequate bowel cleansing by the American College of Gastroenterology, American Gastroenterological Association and the American Society for Gastrointestinal Endoscopy, the recommended protocol is fasting for 24 hours and then drinking a split dose of a 1 gallon oral solution of a prescribed polyethylene glycol (PEG3350/Golytely) based chemical. The mixture is extremely salty to taste, smell, somewhat viscous in texture and challenging to fully consume. The powdered prep is supplied with a powdered flavor packet that comes in artificial fruity/sweet flavors, such as, cherry, pineapple or lemon lime. As an alternative, doctors suggest adding Crystal Lite or Gatorade to the prep solution and then chill in the refrigerator, as an attempt to mask the flavor. Whatever flavor you add, it still tastes like you’re consuming a gallon of very sweet ocean salt water. From the patients’ perspective, the unpleasant taste challenges many from fully drinking the volume of solution and completing the protocol. It has been documented that between 20%-25% of all procedures have inadequate bowel preparation and cannot be successfully completed. During the actual scoping process you are peacefully sedated.

Background: Colon cancer is bad. It is the third most commonly diagnosed cancer and the second leading cause of cancer deaths in men and women combined in the US. The American Cancer Society estimates 150,000+ people were diagnosed last year and 50,000+ will die from colon cancer. The test to screen is a colonoscopy, which is an endoscopic examination and requires the bowels to be completely cleansed prior to the procedure. A colonoscopy prep is a prescribed oral solution that is an osmotic laxative indicated for cleansing the colon for preparation prior to a colonoscopy procedure. According to a 2015 consensus document for adequate bowel cleansing by the American College of Gastroenterology, American Gastroenterological Association and the American Society for Gastrointestinal Endoscopy, the recommended protocol is fasting for 24 hours and then drinking a split dose of a 1 gallon oral solution of a prescribed polyethylene glycol (PEG3350/Golytely) based chemical. The mixture is extremely salty to taste, smell, somewhat viscous in texture and challenging to fully consume. The powdered prep is supplied with a powdered flavor packet that comes in artificial fruity/sweet flavors, such as, cherry, pineapple or lemon lime. As an alternative, doctors suggest adding Crystal Lite or Gatorade to the prep solution and then chill in the refrigerator, as an attempt to mask the flavor. Whatever flavor you add, it still tastes like you’re consuming a gallon of very sweet ocean salt water. From the patients’ perspective, the unpleasant taste challenges many from fully drinking the volume of solution and completing the protocol. It has been documented that between 20%-25% of all procedures have inadequate bowel preparation and cannot be successfully completed. During the actual scoping process you are peacefully sedated.

Invention: Our innovation, PrepAdd™, embraces the inherent salinity of the PEG3350 solution. We have developed a proprietary flavor profile from a blend of ingredients, that when combined with warm tap water mimics a savory chicken bouillon soup, one of the few food items allowed while fasting. When mixed, it produces a palatable drink and a sense of satiation for the patient. It’s completely vegetarian in composition and made from all natural ingredients that are vegan-based, dairy-free, gluten-free, sugar-free, lactose-free, allergen-free, kosher, halal and with nothing artificial. Can also make it taste like beef, pork or roasted vegetable bouillon soup.

When you first bring the glass to your nose you get a whiff of comforting chicken soup. Upon drinking, you get the warm sensation of nourishment and calming to your stomach.

When you first bring the glass to your nose you get a whiff of comforting chicken soup. Upon drinking, you get the warm sensation of nourishment and calming to your stomach.

Packaged separately, you simply add the PrepAdd™ into the prep and add warm water. Flavor additive can be fabricated as a powder, self-dissolving tablet or liquid. Testing for palatability and efficacy of bowel cleanse can be accomplished thru a standard IRB study.

Development is complete.

US Market size:

- 35 million, age 50+ people annually of whom it is recommended should get a colonoscopy to test for colon cancer

- Only 50%, age 50+, 17.5 million, get. Most common reason for not – “the taste and challenge of drinking the prep”

- 22 million, age 45-49 just recommended for screening by American Cancer Society, 5/18

- 1.5 million people with IBD, inflammatory bowel disease

- 750,000 with Crohns disease or ulcerative colitis

- 750,000 with familial hereditary conditions such as, Lynch syndrome

- Using my personal economic beer rule, I would gladly pay the value of a 6-pack, $9.99 for the flavor. Only a guess on what someone else would pay, but, if you’ve drunk the stuff already, it could be priceless. Potential market: $$$ X 60,000,000

- 150,000+ diagnosed annually with colon cancer -3rd most diagnosed cancer

- 50,000+ deaths annually from colon cancer – 2nd leading cause of cancer deaths

- 20%-25% of all procedures cannot be completed due to inadequate bowel preparation

- Patients with opioid addictions and obesity are more often constipated and require 2X prep applications

- American Cancer Society is trying to promote and get 75% of market tested

Regulatory issues:

- By not mixing the PrepAdd™ directly into the prescribed PEG3350 and distributing it in a separate package, it would be classified as a Class 1 device, only requiring registration with the FDA.

- Can be sold as OTC product

- No human trials needed

Intellectual property:

- Patent: filed patent application with USPTO as an invention related to the “Composition of Matter & Method of Usage”

- Trademark: Notice of Allowance issued from USPTO to cover brand, PrepAdd™

- Domain: www.prepadd.com

Accomplishments to date:

- Have developed proprietary flavor recipe

- Have filed patent application to protect product, method of consumption and packaging

- Branding the product: PrepAdd™

- Supply chain; have sourced ingredient suppliers and costed-out recipe for production

- Located potential partners for licensing product

- Have performed human trial on-self for recent 10th colonoscopy. It was delicious!

My very clean upper and lower intestine!

Goals:

- Goal for patient: Increase palatability to enhance user experience and expand potential user base.

- Goal for doctors: Increase successful screening of patients by expanding adenoma detection rates.

- Goal for project: Have everyone drinking a better tasting colonoscopy prep for proper bowel cleanse and early cancer detection.

End game:

- License IP/recipe to an existing FDA approved prep manufacture, or;

- License IP/recipe to pharmacy chain, or;

- Bring PrepAdd™ to market as an aftermarket OTC product, or;

- Create an online home delivery “care package” service to include; allowable foods during 24 hr. fasting period, PrepAdd™, lots of baby wipes and inspirational messages, and;

- Donate % of profits to American Cancer Society to assist educational programs to increase the number of people who get colonoscopies.

Principle investigator: Brett Stern, Portland, OR www.brettstern.com

- As an industrial design consultant, spent 7 years within Pfizer’s Pfresh Tech, an internal think-tank, to invent/develop surgical instruments and implantable medical devices. Functioned as internal hands-on inventor/entrepreneur. 6 of my 8 utility patents are related to the medical field.

- Was the creator/founder of Beer Chips® – potato chips made with beer snack foods, where I figured out how to put beer into potato chips without making then soggy. Developed & sourced all of the flavor profiles of product line. Brought product to market in a self-funded entrepreneurial fashion. Project was successful that a national snack food company purchased assets, recipes and IP within 4 years of introduction.

- My father survived colon cancer, my brother did not. Recently, had my 10th colonoscopy with 2 benign polyps removed. I am highly motivated to bring this product to market.

More info: Want to know more or have an upcoming colonoscopy and want to try some PrepAdd™?

Contact our friendly Bowel Support team

Posted in Inventor

Comments Off on PrepAdd™

99 Ways To Open A Beer Bottle Without A Bottle Opener

It’s every beer drinker’s worst nightmare—a cold brew in hand with no means to open it. Here to the rescue is an indispensable guide featuring 99 ways* to get the job done fast using anything and everything in sight as a bottle opener in a time of need. Photographs and step-by-step instructions for each method walk thirsty readers through the art of opening bottles, revealing the practical use of such handy available implements as a belt buckle, TV remote, baby carriage, dog collar, ski binding, golf club, park bench, BBQ grill, lawn mower, automatic teller machine, police car, and many more. Cheers!

*Plus one: the spine of this hardcover opens bottles, too.

Posted in Writer

Comments Off on 99 Ways To Open A Beer Bottle Without A Bottle Opener

Writer

| We’ve all been there and know how frustrating it is to have that cold, frosty, thirst-quenching beer in hand and suddenly realize that you can’t open it. We cannot always “be prepared” like a Boy Scout, but with this handy “how-to” reference guide, your problems will be solved. You will be able to accomplish this simple task no matter what environment you find yourself in. This manual has examples for a variety of common situations and circumstances that you many encounter. They include: | |

|

|

| Published by: |

|

As you use and apply this information, you will soon realize the variants possible and come up with your own solutions. Let’s face it, all you’re doing is prying a round piece of metal off a round piece of glass. To accompany each example, I have instituted a skill-rating system. After the instructions, there is a beer bottle system for degrees of difficulty.

EASY

MEDIUM

MEDIUM

HARD

HARD

I wish you luck and happy beer drinking. Always remember: NEVER DRINK FROM THE BOTTLE IF YOU BREAK THE GLASS!

Fire Hydrant

1. Follow arrow on top, “Open”

2. Place cap in recess between screw and nut

3. Press down

4. Drink

Back to List

Police Car

1. Make sure nobody is in the car

2. Place cap in trunk lid

3. Press down

4. Drink

5. Don’t get caught

Back to List

Back to List

Toilet

1. Place cap in between valve and pipe

2. Press down

3. Drink

Back to List

Back to List

Pool Bridge

1. Hold bridge near the end

2. Place cap in opening

3. Press down

4. Don’t spill any on the table

5. Drink

Back to List

Back to List

Newspaper Vending Machine

1. Pretend to read headlines

2. Place cap in coin return

3. Press down

4. Drink

Back to List

Back to List

Computer

1. Place cap in hard drive slot

2. Pry off carefully

3. Drink

4. Play some more computer games

note: this will probably

scratch your computer, but it will open your beer

Back to List

Roller Blades

1. Place cap in between shoe and blade

2. Pry off

3. Drink

Back to List

Back to List

Belt Buckle

1. Undo buckle (don’t let pants fall)

2. Adjust buckle accordingly

3. Pry off

4. Drink

5. Don’t forget to buckle up

Back to List

Back to List

Ski Binding

1. Ski all day

2. Go to lodge

3. Lean ski against wall

4. Place beer in toe binding

5. Press down

6. Drink

Back to List

Back to List

Teeth

1. Must be totally desperate

2. Place cap inside mouth

3. Bite off (be careful*)

4. Drink and enjoy

*Remember kids, don’t try this at home!

Back to List

Got a better idea? Let me know.

Posted in Writer

Comments Off on Writer

Recycled Benches

Question:

What do you get when you smash a toilet bowl into a zillion pieces?

Answer:

A method for recycling.

Created a proprietary concrete matrix material that applies the usage of fired ceramic product, such a toilet bowls, urinals and dishes and turns it into finished goods.

The domestic ceramic sanitaryware industry currently manufactures approximately 20.94 million individual units (toilet tanks and bowls, urinals, sinks, bidets) with the amount of secondary waste produced exceeding 35,869 tons per year. Project prposed to take these toilets and create an aggregate raw material out of them. The crushed material can then be designed into manufactured industrial and consumer products. The goal is to fabricate objects that use as their structured content the recycled clay, just as glass bottles, plastic containers and newspapers are recycled today back into products.

A typical concrete composite has as its weight content over 50% aggregate in its mixture. The concrete industry currently uses over 2 billion tons of gravel per year. Therefore, with just a 1% penetration into the aggregate industry, there would be a market demand for over 20 million tons of ceramic aggregate annually. If the penetration reached 1.79% the complete waste of the sanitaryware industry could be consumed.

| Park benches | Picnic tables | Playground furniture | Road barriers |

| Parking bumpers | Garden furniture | Fountains | Trash/waste cans |

| Bollards | Flooring tile | Terrazzo products | Planters |

This park bench is an example of this application. Imbedded into the cement mixture was once a complete toilet bowl and tank weighing 52 pounds.

Posted in Inventor

Comments Off on Recycled Benches

Wood Kiln

Visiting artist/engineer, Alfred University – ceramic department, 2003-2005 was asked to investigate the development of a method to reduce the amount of pollutants being released from the wood burning kilns on campus that exceeded EPA/NYS-DEC air quality standards.

Wood fired kilns come in many assorted shapes, sizes and firing attributes, but all require a continuous tending and stoking of wood throughout the process, which lasts from several hours to several days. During this process the “fly ash” from the burning wood is drawn from the firebox into the chamber where the pots sit. This ash settles and eventually fluxes and melts to form a natural ash glaze on the surface of the pottery.

To create as much ash as possible a typical stoking occurs every 7-10 minutes. The kiln is typically fired in a reduction atmosphere, which starves the kiln fire of oxygen. The downside is that this causes a release of heavy black smoke (carbon monoxide), particulates, hydrocarbons and release of air contaminates into the atmosphere over the continuous firing process from the chimney flue.

Solution covers the method of placing a catalytic combustor (convertor) in the chimney flue to burn the fuel more efficiently and burn-off unwanted contaminate. Exhaust gases can be routed through a catalytic combustor: a ceramic or metallic matrix material that is coated with a metal such as platinum or palladium. Smoke, gases and particles pass through the combustors surfaces and ignite at a much lower temperature (250°C) than they would without the combustor (500°C). The result is that harmful substances are more completely burned. The process is passive, relatively maintenance free and of reasonable costs over an estimated 5-year lifecycle. Preliminary test results reduced particulates by 85-90% during the process and did not effect firing schedule or ash effect on ceramic work.

http://www.sururalism.com/brettstern/wp-content/uploads/2010/04/wood_kiln.flv

Posted in Inventor

Comments Off on Wood Kiln

Plable

Ceramic tiles- one side flat, the other recessed for eating. Tiles sit in table surface. When ready to eat, push down on the edge of tile and turnover. Are you eating on the plate or are you eating on the table? The middle tiles have inserts for serving dishes, candle holders or centerpieces.

Posted in Inventor

Comments Off on Plable

Formafit

Automation for a sustainable apparel manufacturing industry

The Formafit process is an automated method for apparel manufacturing. The goal is with the adoption of this process*, it could create decentralized microfactories to facilitate a renaissance for the domestic apparel industry; to produce on demand garments by new-shoring production, reduce lead-times and expand job creation in the manufacturing sector. It will boost the value chain of companies by expanding sell-through, responding quicker to market demands, reduce overall waste, lower total material and energy resource consumption and offer an immediate opportunity to embrace sustainability and labor issues that consumers are demanding. At present, 98+% of apparel that we buy in the US is offshored, with those domestic apparel jobs and skills lost generations ago and not coming back. Once stable, offshore supply chains in the garment manufacturing sector are now being disrupted by trade wars, uncertain and rising tariffs and global pandemics.

The Formafit system embraces industry 4.0 factory automation standards to become a smart factory by enabling a connectivity and merging the mechanical with the digital, to produce clothing, a basic element of human life, in an efficient/cost effective way. The uniqueness of the system is that we keep that flexible fabric stationary and move the machinery around, using industry standard automation technologies. It goes from bolt of cloth to a finish garment and applies 3D fabric molding and ultrasonic bonding technologies to simultaneously affect the shape of the garment and the cutting/seaming of materials, all off-the-shelf components**. The process requires the usage of synthetic fibers, such as, polyester, nylon, spandex and polypropylene, can accommodate a variety of knit, woven and non-woven fabrics, all off-the-shelf materials and can readily accept recyclable content in its composition. With the applied technologies, the process has application to manufacture sportswear, athleisurewear, outdoor clothing, military and work uniforms, career apparel, medical grade garments and personal protective clothing.

The first generation machine will have the capacity for continual replication of exact copies of designed product that converts 2D fabrics into soft/flexible 3D garments. The Formafit process is flexible in fabricating a variety of types of garments, ranging from loose-fitting styles to highly contoured designs. With this alternative method for manufacturing, it will also establish a novel aesthetic vocabulary for the fashion designer. One that the designer already models in a 3D format on a computer to better fit the human body, as well as, offer increased performance and added comfort. Additionally, with the development of smart fabrics, tending to be synthetic in construction, the process has the potential to produce a whole new class of smart clothing, whose functionality would be technologically restricted and cost prohibitive by using traditional cut and sew methods.

Nylon/Spandex –athletic, athleisure apparel ***

Polyester -military uniforms, career apparel***

Microfactory: need clothing for the New York or Los Angles or Oshkosh markets? Build out a neighborhood microfactory to manufacture only what you need for local distribution and consumption in real time. The process offers transparency and traceability of production, creates local manufacturing jobs, and makes “Made Here” clothing. Won’t need to plan 6-9 months out for offshore production, which ties up capital and offers limited quality control.

Macrofactory: scale up and expand the entire process to create a configuration that goes from fiber, to fabric, to finished garment. Incorporate recycled plastics for grinding back into polymer pellets to extrude into fiber, which could then be processed into an assortment of recycled fabrics, which could then be fed directly into the machine, to produce upcycled clothing. Integrate renewable energy resources to allow for the efficient throughput of recycled raw materials to finish garments to create a self-contained facility to manufacture apparel in a truly sustainable format.

Minifactory:scale down the process for a storefront retail operation. A consumer could step onto an augmented reality (AR) platform to have their body 3D scanned and with a fashion designers’ input or software suggestions from their phone app, select a garment design, print on-demand graphic patterns on the materials, to create a unique garment in real-time. Partner with sport teams or spin class studios or theme parks or any type of entertainment event and produce branded apparel on premise, on demand, for immediate sales.

On demand factory: the process has the ability to fabricate surgical scrubs or disposable medical garments that use synthetic non woven materials. Onsite, at a hospital could be a self-contained on demand factory designed to function well within the facilities limited space and produce a daily allotment of garments per operational schedule.

Fastfactory: in an emergency situation, such as, a pandemic or natural disaster, a fastfactory could be quickly inserted into the environment by FEMA or the National Guard for operation in a medical support tent to ramp up quantities to provide medical grade garments and personal protective clothing to assist in meeting the immediate demands.

Portafactory:construct a self contained portable system with the ability to deliver by truck, ship or plane and be transported by a governmental agency/NGO to bring to areas for emergency response and production.

All of the technologies for these scenarios exist, except on the garment production side.

This is what we are proposing.

Advantages:

- Increase sustainability of production

- Reduce lead time and inventories

- Increase value chain by expanding sell-through

- Reduce energy usage for production & distribution

- Decentralize production

- Increase capacity to make a new style/fashion of garment designs

- Increase labor conditions

- Embrace domestic job creation

- Offers transparency and traceability of production

- 0% tariffs, 0% quotas

- Make Made in America again

*The process uses fabric molding, ultrasonics and factory automation, similar to the production of N95 masks and PPE medical gowns.

**Have proven the technical feasibility of the project with funding from Small Business Innovation Research grants (SBIR):

- National Science Foundation

- U.S. Department of Energy

- New York State Science and Technology Foundation

- New York State Energy Research & Development Authority

*** Prototype garments made by simulating the process

Posted in Inventor

Comments Off on Formafit

Ice Cream Cone

Molded waffer ice cream cone. Melted ice cream drips into outer gutter and into interior of cone.

Posted in Inventor

Comments Off on Ice Cream Cone

Sprout Spout®

Finally, there’s an easy-to-use way to end kids’ spills! This universal spill-proof cap turns any 16 0z. (and up) store-bought plastic juice container into the equivalent of a sip cup. The special one-piece cap automatically prevents fluid from spilling or leaking – even if dropped or tipped over.

It screws snugly onto the industry-standard neck of plastic non-carbonated beverage bottles. The fully automatic valve opens and closes tightly in response to drinking pressure. Made of non-toxic, high-density polyethylene. Durable, reusable and dishwasher-safe.

In addition to design efforts, found client a domestic manufacturer that was already producing internal valve components for an alternative function, saving on engineering development and tooling for production.

www.sproutspout.com/

Posted in Industrial Designer

Comments Off on Sprout Spout®

Selective Vascular Compression Device

Client:Pfizer Inc., Scheider (USA) Division, Strategic Innovation Group, Pfresh Tech Think Tank.

For use during radial angioplasty heart surgery, a compression device for selectively applying compressive force to a localized area of interest on the body surface that is readily positioned and fastened in place.

US Patent #5,569,297

“Selective vascular compression devise”

European Patent, #95926476.3-2305

“Selective vascular compression devise”, Designated states; AT, BE, CH, DE, DK, ES, FR, GB, GR, IE, IT, LE, LU, NL, PT, SE.

Assignee: Schneider (USA) Inc., Plymouth, MN. 1996

Assignee: Schneider Inc. (Europe), 1997

Posted in Industrial Designer

Comments Off on Selective Vascular Compression Device

Mr. Freeze Costume

Posted in Industrial Designer

Comments Off on Mr. Freeze Costume

Implantable Access Device

Client:Pfizer Inc., Valley Labs Division, Strategic Innovation Group, Pfresh Tech Think Tank.

For dialysis procedures, an implantable access device for allowing repeat access to a site within the body of a patient, which allows for the passage of fluids, filaments or therapeutic agents.

US Patent #5,741,228

“Implantable access device”, 1998

Assignee: Horizon Medical, Atlanta, GA.

Posted in Industrial Designer

Comments Off on Implantable Access Device

Guide-pin Placement Device

Client:Pfizer Inc., Howmedica Division, Strategic Innovation Group, Pfresh Tech Think Tank.

Methodology for placing a femoral hip screw in femoral head to repair a hip fracture. A hand-held instrument and method for use by a surgeon to target the appropriate entry point and trajectory on bony tissue through which an instrument or implant is passed.

US Patent #6,520,969

“Guide-pin placement device”, 2003

US Patent #6,214,013

“Method of using a guide-pin placement device”, 2001

US Patent #6,036,696

“Guide-pin placement device and method of use”, 2000

Assignee: Stryker Technologies, Kalamazoo, MI.

Posted in Industrial Designer

Comments Off on Guide-pin Placement Device

Gothic Revival Castle

Commissioned to design and build the interior of a castle in the Gothic Revival style. Site location is the West Village of New York City. Client collects decorative arts of that period and requested the renovation of a 3,500 sq.ft. loft to match his collection. Work consisted of historical research, sourcing original suppliers and materials from the time period, overall design and engineering of space, construction and carving of all wood pieces and installation of all woodwork and tile and hanging of artwork.

Posted in Craftsman

Comments Off on Gothic Revival Castle

Ceramics

Clay is my favorite material. My afterschool job in high school was as an apprentice to a potter. I got to learn the craft from an old school perspective. This included rolling out clay slabs with a metal pipe and mixing all of the lead-based glazes without a respirator. Great way to learn and respect any material. Has provided a method to explore and use other materials ranging the full spectrum of natural to synthetics and tools, both hand and mechanical to process them.

Marble Bathroom

There is a method to Brett’s madness. To complete the renovation of this new bathroom, he glued 25,132 glass marbles on to the floor, walls, ceiling, tub, doors and sink counter. The glass pieces are amorphic in shape, about an inch in diameter, 3/8″ thick, flat on one side and domed on the other. A combination of clear and frosted clear marbles were chosen to give a sublime texture to the surface. And yes, each marble was glued in place one at a time.

The marbles are sized small, approximately 5/8″ diameter and large, roughly 1″ diameter. The small size is available in thirty-two colors and the large in twelve. The colors are either translucent, opaque or cat’s eye. They are naturally glossy, but can be made frosted or with an iridescent finish. I’ve done an installation with 105,000 marbles and can’t wait to do 1 million. Anybody want a pool done?

* 6 days of gluing, 2 days of grouting, 1 day of cleaning.

Posted in Craftsman

Comments Off on Marble Bathroom

Inventors at Work

Purchase Information

Website

Retailers and Ebooks

Amazon.com |

Apress.com |

Barnes and Noble |

This book is a collection of interviews conducted with individuals who have distinguished themselves in the invention space. Some of the inventors interviewed here have their Aha! moments in government, institutional, or industrial labs; develop their inventions with multidisciplinary teams of experts; and leave the marketing of their inventions to other specialists in the organization. Some inventors in this book develop their inventions with small teams in academic labs and try to translate their research into product via licenses or startup companies. Other inventors I interviewed carry on the classic lone-inventor-in-his-garage tradition and take on the task of bringing their products to market themselves. And a few mix and match their strategies, bringing skills honed in big labs home to their garages and licensing their personal inventions to big corporations.

This book is a collection of interviews conducted with individuals who have distinguished themselves in the invention space. Some of the inventors interviewed here have their Aha! moments in government, institutional, or industrial labs; develop their inventions with multidisciplinary teams of experts; and leave the marketing of their inventions to other specialists in the organization. Some inventors in this book develop their inventions with small teams in academic labs and try to translate their research into product via licenses or startup companies. Other inventors I interviewed carry on the classic lone-inventor-in-his-garage tradition and take on the task of bringing their products to market themselves. And a few mix and match their strategies, bringing skills honed in big labs home to their garages and licensing their personal inventions to big corporations.

This is not a recipe book. It doesn’t aim to reduce invention to a series of foolproof steps: how to take an idea, go through the R&D process, develop prototypes, create intellectual property, build a brand, raise capital, and get product on store shelves. Rather, this book invites readers to touch their own creative impulses to the fires of real inventors speaking candidly about what possesses them every day of their lives: the passion to invent.

These privileged conversations have confirmed my belief that inventors are born to be inventors. Of the multitudes of clever people who get technical degrees in engineering and scientific fields, only a fraction contrive to add patents to their credentials. It is the rare individual who can combine curiosity, intellectual powers, mechanical knack, and focused awareness to see a novel solution to a problem and then convert that insight into a physical invention that works. (For the sake of coherence, I decided to interview only the inventors of physical products, and not the inventors of software products.)

This collection of interviews shows how a startling variety of inventors—selected for their widely divergent backgrounds, educations, fields, interests, personalities, age, gender, ethnicities, business circumstances, and invention types—share the ability and indeed the compulsion to create ideas and objects that are useful, exciting, and unprecedented. Some of the inventions described here by their creators have transformed the world; others simply made the world a more fun place to live. But all of these different inventions drew on an array of common traits in their inventors: perseverance, drive, motivation, a touch of obsession, and—most importantly—the welcoming of failure as a opportunity to learn and push their ideas forward.

The intent was to talk about the process they go through, not so much the product they invented. I was also struck by the fact that most of the inventors I interviewed expressed a similar set of preferences and work habits. They like to work on multiple projects simultaneously in multidisciplinary teams, freely sharing their ideas with others. They reach out to experts in other fields and ask lots of questions. They wake up in the middle of the night and sketch out their ideas on paper or visualize them vividly in their heads. They prototype ideas using materials that they are comfortable working with. They use physical exercise to relax their minds and jack up their concentration. They seek mental stimulation and different tempos of thought in areas outside their specialties. Most strikingly, they value slow time to ponder alternative opportunities. And finally, they said they would never retire from being an inventive person or stop working on a project that interests them.

COPYRIGHT 2012: Brett Stern – ALL RIGHTS RESERVED.

Posted in Writer

Comments Off on Inventors at Work

Beer Chips®

Beer Chips® – Potato chips made with beer

Hot Potatoes® – Spicy Bloody Mary potato chips

Chip Shots® – Margarita with salt potato chips

Chief Chipper-inventor/owner. Launched an entrepreneurial business to create and market a line of adult snack foods. Set up a virtual manufacturing business model to outsource everything except the creativity. Branded/designed product and created all intellectual property (trademarked in 34 countries). Developed flavor profiles, sourced ingredients, suppliers and co-packers. Designed packaging and all related collateral materials for day to day business operations. Created marketing and sales campaign for product and got placement in planograms without slotting fees in major retail supermarkets/box stores throughout US and abroad. Hired/managed office staff, established broker/sales network and set-up distribution channels. Lead sales person with first year revenue exceeding $500K, 2nd year $1.3 million+ and sold company assets at the end of 3rd year to national snack food manufacturer in 2010.

Posted in Inventor

Comments Off on Beer Chips®

Coffee Cup Lid

Every morning I go out for a cup of coffee and a bagel. By the time I get to my office, the coffee has leaked out of the top of the coffee container, soaked the napkins and made the bagel all soggy. To solve this problem I decided to invent a beverage cup lid that doesn’t leak.

My solution to stop the leak from the small vent hole on the top of the lids is to apply a proprietary filter material, which allows air to flow through the vent hole, while retaining the liquid inside the container. The vent hole can be anywhere on the lid and the filter material can be fabricated in a variety of colors.

This invention will prevent unwanted release of hot or cold liquid, which has the ability to burn the user or create an unsanitary and messy condition. In the case of a hot coffee spill, clothing, furniture, carpeting, car interiors and any surrounding surfaces may be stained, any other contents of the soggy bag are typically soaked and spoiled. Moreover, hot coffee and the like can cause scalding as it is ejected out of the container upon impact leaving the vendor open to liability.

U.S. Patent #5,988,426

Posted in Inventor

Comments Off on Coffee Cup Lid